Lightweight insulating concrete (LWIC) provides permanent, sustainable, reroofable insulation that both reduces temperature fluctuations and increases membrane longevity. For decades, SERD Construction has been a leading installer and applicator of LWIC roof decks across the Southeast, for roofing and reroofing of schools, hospitals, commercial buildings, and other structures.

Why Choose LWIC Roof Decks?

What makes LWIC roof decks the ideal choice for large commercial or institutional buildings? Here are just a few advantages of LWIC roof decks over traditional tapered insulation systems.

- Stable insulation value: Unlike polyiso boards, which lose a percentage of their R-value every year, LWIC roof decks maintain a stable R-value across the life span of the roof.

- Reroofing efficiency: LWIC roof decks do not need to be torn off during reroofing, saving roofing contractors significant time, money, and environmental impact. Only the roofing membrane needs to be removed and replaced.

- Membrane longevity: Raising the temperature of a roof membrane can significantly decrease its life span. The excellent thermal insulation properties of LWIC roof decks reduce temperature fluctuation on the membrane, leading to greater longevity.

- Lower environmental impact: LWIC roof decks reduce waste generated during reroofing (less debris that needs to be disposed of in a landfill). Additionally, their thermal insulation properties reduce energy consumption of the building.

- High compressive strength: LWIC roof decks can achieve high psi. LWIC is a durable substrate for a roofing membrane and acts as a stable and supportive base.

- Positive slope: With traditional tapered insulation systems, multiple layers of board are required to achieve a positive slope. To create slope in LWIC roof decks, we simply cut the EPS holey boards to the appropriate thickness to ensure effective drainage.

- Fire rating: LWIC is a non-combustible material, making it inherently fire-resistant. LWIC roof deck systems can achieve high hourly fire ratings and do not require additional fireproofing on the underside of the metal deck.

- High wind uplift resistance: LWIC roof decks are a good choice for coastal or high-rise buildings, because the lightweight insulating concrete bonds extremely well to existing approved substrates as well as galvanized metal deck in new construction. This bond offers excellent wind uplift resistance.

- Composite action: LWIC roof deck systems can use a lighter gauge metal deck, because the metal deck and LWIC layer work together to create a stronger roofing system.

Lightweight Insulating Concrete Brands We Install

SERD is a licensed applicator of Siplast, Aerix, and Elastizell, three leading LWIC brands.

SERD Is a Leading Installer of Metal Deck with Lightweight Insulating Concrete

LWIC is often combined with galvanized steel deck to create a composite roof deck system yielding superior vertical loading, diaphragm, and wind uplift. We have decades of experience not only assisting in the design of these systems but actual hands-on knowledge of how the systems come together in the field. These combination systems range from standard metal roof deck to form deck and even to metal acoustical roof deck systems.

Pre-Spec Services for Roof Decks

Our team of experts works with architects and engineers to specify their roof deck system before the project begins. We value engineer your project to meet your building’s needs while maximizing your budget. Our design assistance includes:

- Product/system selection

- Loading/diaphragm/uplift

- Roof/slope plan

- R-value calculation

- Acoustical analysis

- Guide specifications

- Budget pricing

- Field product demos

Where We Work

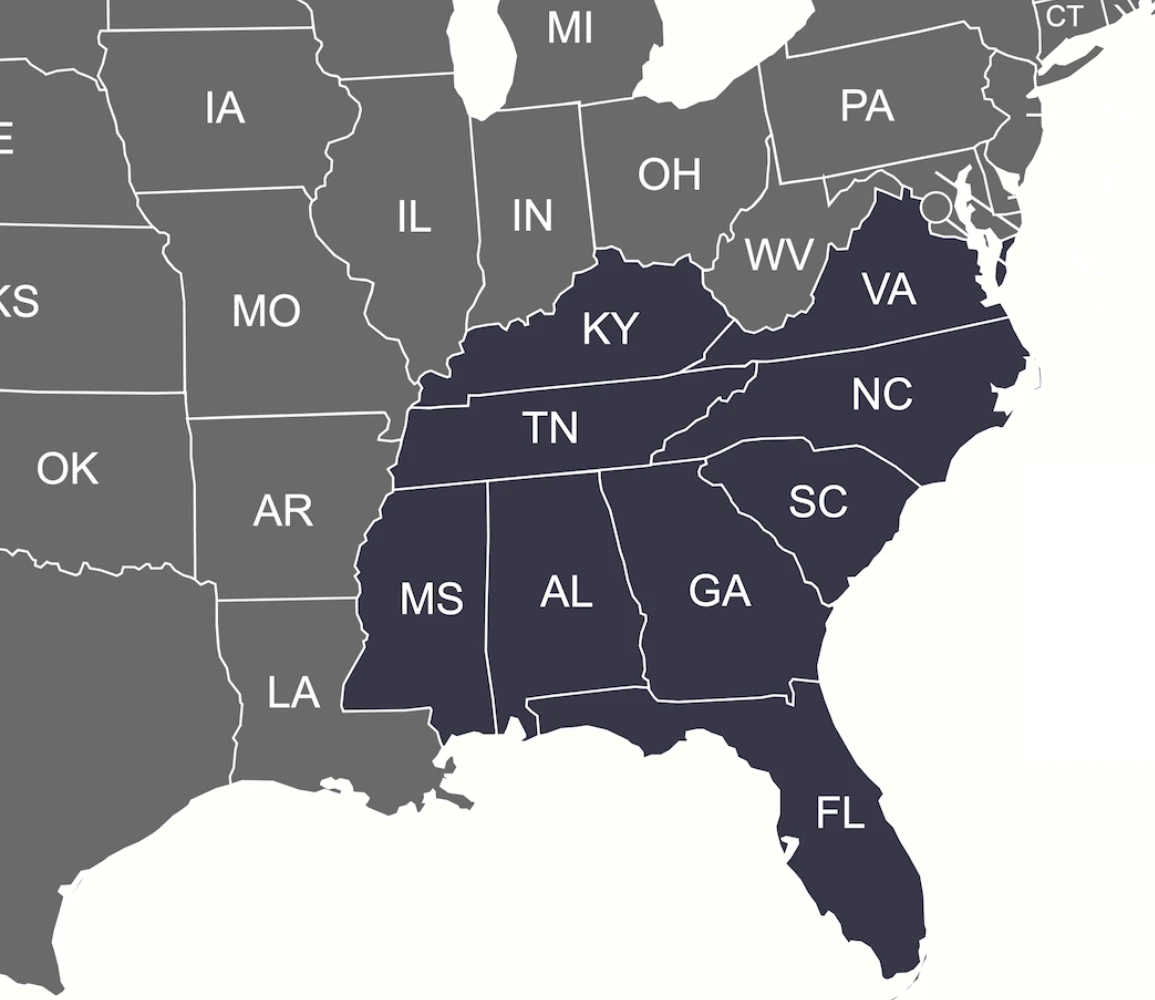

We’re a leading installer of roof decks and engineered fill across the Southeast, including Alabama, Tennessee, Kentucky, Virginia, Mississippi, Western Carolinas, North Georgia, and the Florida Panhandle. If you have a project outside that region, contact our sales team to discuss our capabilities.