What is Engineered Fill?

Engineered fill, also called low density cellular concrete, cellular grout, and flowable fill, provides nearly unlimited geotechnical applications to suit project needs. The material is both lighter and stronger than traditionally compacted soil and flows easily into all spaces, eliminating potential voids. In addition, it is cost-competitive both during installation and throughout the life of the product.

When to Use It

Engineered fill is typically used when compacted soil creates unacceptable risk.

This includes projects with weak or inconsistent soils, long placement distances, confined spaces, or conditions where added weight or lateral pressure must be controlled. It is also commonly used when traditional compaction is impractical or when predictable performance is required adjacent to utilities, structures, or infrastructure.

On many SERD projects, engineered fill is introduced to solve problems identified during design or to address unforeseen conditions encountered during construction.

Technical Specs

Density

Unit weight is tailored to meet load limitations and site conditions, allowing use where soil or conventional concrete would overstress subgrades or surrounding structures.

Compressive Strength

Strength is defined by application requirements and can be limited to allow future excavation where necessary.

Flowability

Material is highly flowable and capable of filling confined spaces and voids while maintaining consistent placement over extended distances.

Lateral Force

Exerts lower lateral pressure than compacted soil, reducing risk when placed adjacent to walls, utilities, and existing structures.

Standards & Testing

Designed to meet project-specific requirements and applicable standards, including ACI 523 and relevant ASTM test methods for density and strength.

Common Applications of Engineered Fill

Transportation & Civil Infrastructure

Used for roadway embankments, bridge approaches, and infrastructure fills where settlement control and load reduction are required.

Structural & Commercial Site Work

Applied under slabs and site structures where weight limits and predictable performance are critical.

Utility, Trench & Underground Applications

Used in pipe trenches, shafts, and utility corridors where compaction access is limited or future excavation is anticipated.

Void Fill & Remediation

Placed in abandoned structures, tunnels, mine voids, and underground spaces where complete void penetration and long placement distances are required.

Environmental & Specialty Applications

Used for specialty remediation, encapsulation, and applications where conventional fill presents long-term performance risks.

Why Choose SERD Engineered Fill Over Other Fill Options?

Generic flowable fill can only be pumped about 100 feet away and offers lower performance compared to SERD engineered fill. We optimize the weight, strength, and flowability of engineered fill to reduce horizontal loads and lateral force. Our engineered fill also offers excellent thermal conductivity.

Pre-Spec Services for Engineered Fill

Our team of experts works with geotechnical and civil engineers to design the proper fill material prior to the start of the project. Selection of the proper cast identity for the various portions of the project is important to our team so we deliver products that are not only the highest quality, but also cost-effective. Our engineered fill design assistance includes:

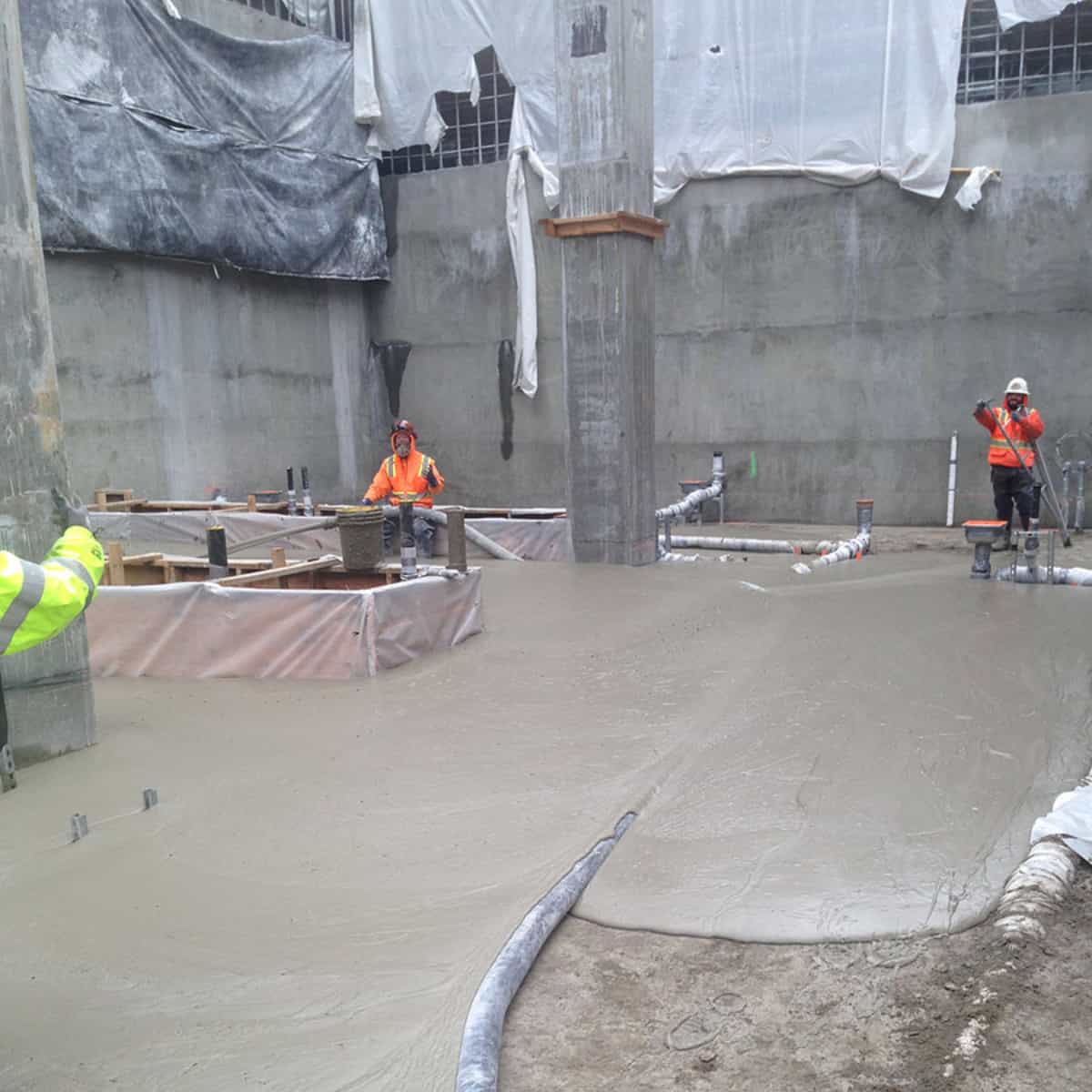

Our Engineered Fill Installation Process

1. Pre-Spec Coordination

Coordinate with engineers and project teams to evaluate applications, budgets, and specification requirements.

2. Mix Design & Technical Review

Develop project-specific engineered fill mixes aligned with geotechnical and design criteria.

3. Pricing & Submittals

Provide budget pricing and required technical submittals to support bidding and approvals.

4. Installation Plan & Placement

Plan site logistics and perform engineered fill placement in accordance with project requirements.

5. Documentation & Closeout

Deliver required documentation and closeout materials to support inspections and project completion.

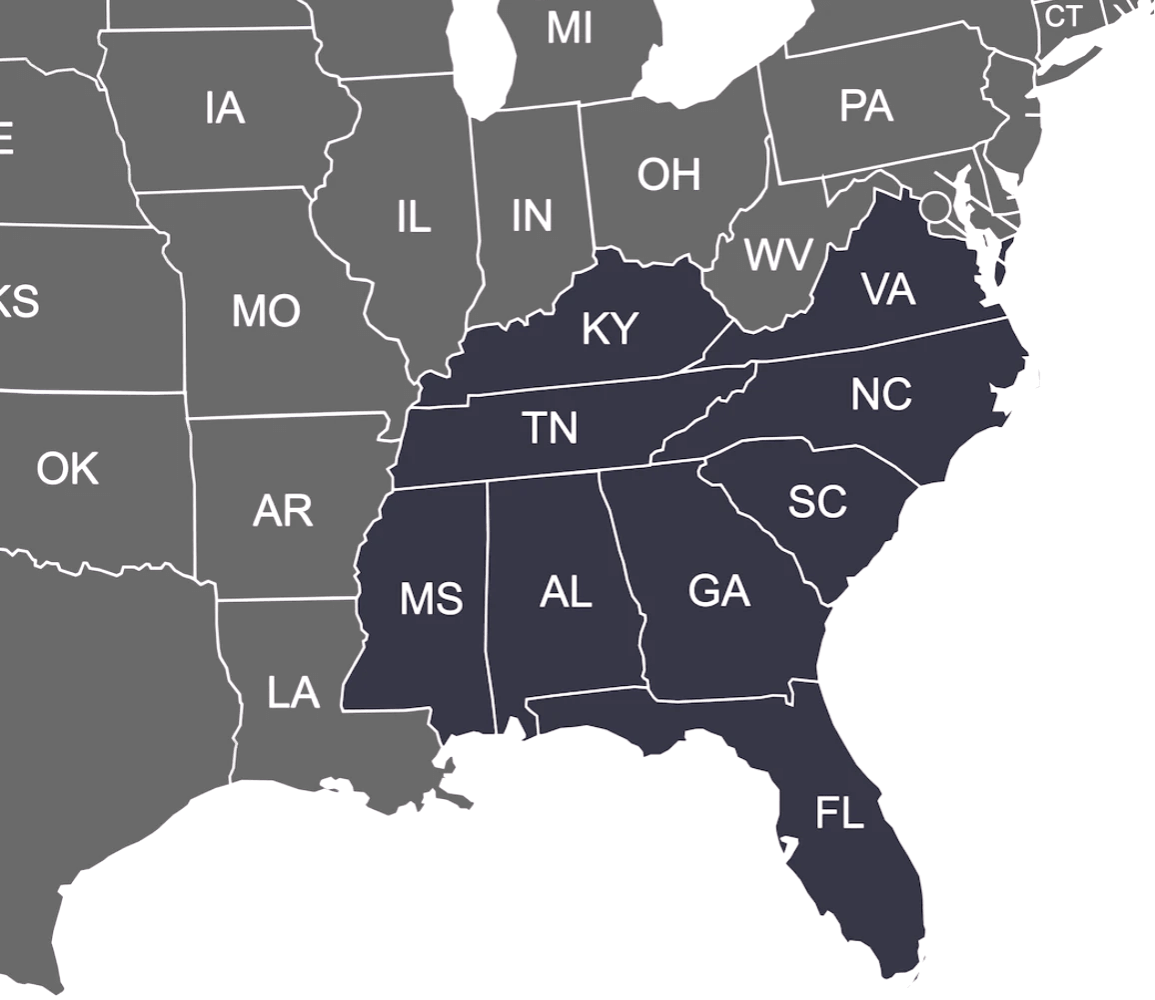

Where We Work

With generations of regional experience, our engineered fill installers deliver reliable solutions for construction projects across Southeast USA.